E-CellTM

E-Cell Design

With more than 20 years of experience in cell designing and manufacturing, ANCOR Sp. z o.o has been able to refine technology in main three aspects relevant to assure a successful supply:

- Raw materials selection: All raw materials utilized during our cell manufacturing process are supplied through premium European companies having CE conformance and fully controlled by a severe QA system.

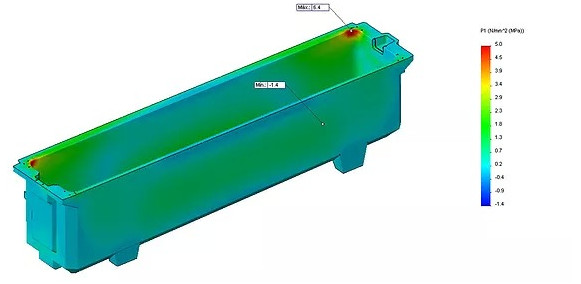

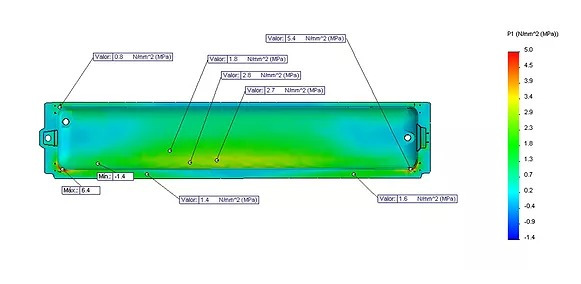

- Expertise in cell design and CAD/FEA calculation: With thousands of cells manufactured, this process has been deeply developed to evaluate not only dead and live permanent loads but also transient loads as found in any normal tank house operation conditions, including seismic activity, anode drop, electrolyte fast filling and environmental sudden temperature changes.

- Proven manufacturing processes, protocols and procedures, closely verified by a rigorous Quality Assurance Plan in strict accordance to ISO 9001:2015 standard and completely opened for customer revision.

E-Cell Manufacturing

Our full monolithic cells are manufactured with premium vinylester resin by a controlled vibration process in steel inverted molds subject to numerous regular controls detailed in our Quality Plan. Each mold can manufacture one cell per day. Therefore, number of molds is critical for project planning purposes.

E-CellTM tanks are manufactured according to a rigorous Quality System that conforms to ISO 9000 and satisfy all their formal requirements.

E-Cell's Polymer Concrete features:

- Chemically inert to electrolytic solution

- Monolithic structure

- Self-supporting

- Easy to transport and install

- Sloped bottom for easier cleaning

- Minimal maitenance

- Non electrical insulation